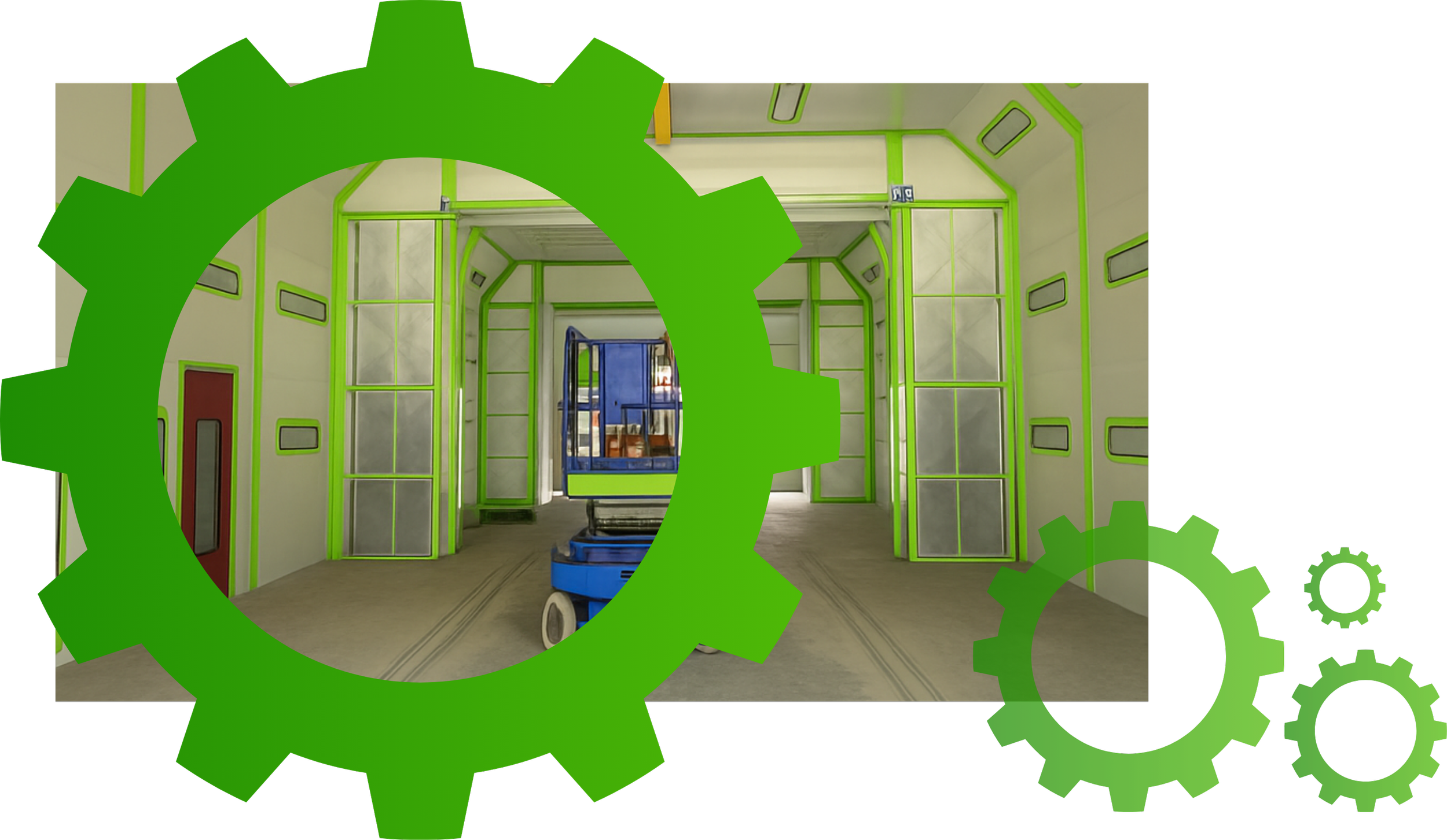

Blasting & Spray Booths / Rooms

Complete Surface Preparation & Finishing Solutions — Engineered for Performance

At Tilvis Engineering, we design, manufacture, and install high-quality blasting and spray booths/rooms that deliver superior surface preparation and finishing results. Whether you’re working with steel structures, automotive parts, heavy machinery or custom components, our systems provide a controlled, safe, and efficient environment from start to finish.

Every booth is engineered to meet your operational needs, improve productivity, reduce contamination, and ensure consistent coating or blasting quality — no matter the industry.

Our Blasting & Spray Booth Solutions

“All of our spray booths are fully compliant with municipal bylaws and meet the approval standards of the local fire department.”

✔ Custom Blasting Rooms

Industrial-grade blasting rooms built for durability and continuous operation.

Features include:

Heavy-duty steel construction

Abrasive-resistant lining

Abrasive Recovery & Air wash Systems

Advanced dust extraction systems

Optimal airflow & visibility

Multiple abrasive compatibility

Maintenance-friendly layouts

✔ Spray Booths (Paint Booths)

High-performance spray booths designed for clean, dust-free finishing.

Options include:

Dry filter booths

Automotive & industrial paint booths

Custom-sized enclosures

Integrated airflow and fume extraction

Temperature & humidity control (optional)

Spray Booths & Rooms

A well-engineered spray booth ensures:

✔ Optimal coating adhesion and finish consistency

✔ Improved worker safety

✔ Effective over-spray and fume management

✔ Enhanced production efficiency

✔ Compliance with municipal bylaws and local fire department approval

Our spray booths are fully compliant and designed to deliver reliable, safe, and efficient finishing processes for your facility.

Blasting Equipment & Rooms

A properly designed blasting system drastically improves:

✔ Surface preparation quality

✔ Component longevity and durability

✔ Dust and debris management

✔ Production efficiency and workflow consistency

✔ Compliance with environmental regulations

Tilvis Engineering manufactures blasting equipment and rooms that meet industry standards while supporting both high-volume and high-precision production workloads.

Complete System Integration

We handle the full build — from design and manufacturing to installation and commissioning, including:

Ducting & ventilation

High-efficiency dust collectors

Lighting & electrical setups

Safety interlocks & fire systems

Air handling and filtration units

Noise & environmental control

Why Blasting & Spray Rooms Matter

Maintenance and Repairs

Tilvis Engineering provides reliable maintenance and repair services to keep your spray booths and blast booths operating safely and efficiently.

Our Services

✔ Preventative maintenance and routine inspections

✔ Filter replacements and airflow optimisation

✔ Mechanical and electrical repairs

✔ Booth refurbishments and upgrades

✔ Fast response for breakdowns and emergency support

We help ensure your booths stay compliant, efficient, and ready for consistent production.

Why Choose Tilvis Engineering

✔ Custom-engineered to your space, process & production volume

✔ Built for durability and heavy industrial use

✔ Superior airflow and extraction systems

✔ Professionally fabricated with premium materials

✔ Seamless installation and after-sales support

✔ Designed for long-term reliability and easy maintenance

✔ Cost-effective solutions without compromising quality

Industries We Support

Manufacturing

Mining & heavy industry

Steel fabrication

Equipment refurbishment

Engineering workshops

Railway

Construction & scaffolding

Whether you’re upgrading an existing facility or building a new production line, we create solutions that enhance workflow and reliability.